Lean production methodology is one technique that can help attain optimal solutions if used properly. Let's take a closer look at lean production and its principles.

Lean production business definition

Lean production is a way of organizing work that focuses on getting the job done as efficiently as possible, without wasting time or resources. It was first used in manufacturing by Toyota and has since been adopted by businesses across many different industries. By using lean production methods, companies can reduce waste, increase productivity, and deliver higher-quality products or services to their customers.

Lean production or lean manufacturing is a production method that aims to create more value for customers with fewer resources. It involves identifying and eliminating waste of time and resources. This approach emphasizes the importance of continuous improvement, teamwork, and waste reduction to achieve maximum efficiency and productivity.

Let's take an example of a pizza restaurant. In traditional production methods, the restaurant may prepare large quantities of pizza dough and toppings in advance to ensure that they are always available. However, this can result in waste if the ingredients are not used in time or if the customer orders a different type of pizza. With lean production, the restaurant would only prepare the necessary amount of dough and toppings based on the orders received. This ensures that the ingredients are fresh, reduces waste, and increases efficiency in the overall production process.

When Sakichi Toyoda founded Toyota and began manufacturing automobiles, the company's volume of production was small compared to giants like Ford at that time. Eiji Toyoda, Sakichi's nephew, went to study Ford's manufacturing system, but soon realized that it couldn't match the mass manufacturing technique of Ford. So the firm collaborated with Taiichi Ohno to design a production process to meet the needs of Japanese customers. They concluded that the best system would be to manufacture according to current requirements and use advanced machines to produce high-quality products faster and at a lower cost. This method came to be known as the 'Toyota Production System' which is now also referred to as Lean Production.

Principles of lean production

The 5 principles of lean production were designed by James Womack and Daniel Jones: value, value stream, flow, pull, and perfection.

Value

The first principle of lean production is value. 'Value' here refers to the benefits that the customers get from the products. Lean methodology suggests that the production system should be such that it adds value to the customers. Value is customer-focused and not company focused.

Value stream

The next principle of lean production is the value stream. Value stream means defining the process of how to manufacture the product in a way that can add value to the customers. Value streams call for a flowchart to be created for each process that may be involved in the production process. Also, If any process is not required or does not add value, it should be discarded.

Flow

The third principle is flow. Flow is the smooth functioning of the value stream process which is defined in the earlier principles. Flow refers to the fact that once all the unnecessary processes have been discarded, the production should run more smoothly without any blocks or delays.

Pull

Pull is the fourth principle of lean production. Once the production flow is in place and there are no bottlenecks in the process, it is possible to deliver the products as demanded. Pull refers to just-in-time production and delivery process. With improved flow, it is possible to give the customer the product when demanded, at the right time and in the right quantity. This results in reduction of stock and inventory costs and adds value to the customers.

Perfection

The last and most important principle is perfection. Lean production suggests that it is important that all members of the organisation are involved in the production process and that all are following the lean production system. As we know the world is ever-changing and demand keeps changing constantly, so it is very important to keep up with the customer's demand and lean production should become an essential part of the production process in the company.

Muda, mura, muri in Toyota Production System

The lean production system emphasises the 3 main elements that need to be considered and eliminated in the process of production

- Muda - waste elimination

- Mura - unevenness of the production process

- Muri - overburden

These elements are discussed below in detail.

Muda - Waste elimination

‘Muda’ refers to all kinds of waste. Lean production methodology states that there are 7 losses in production that can be eliminated to add value to products:

- Defects: Defects can result in heavy losses. It is very important to try and eliminate any defects as early as possible. Lean production suggests that defects can be prevented by checking the production in the first place which can stop them from happening or removed from the final steps of production.

- Waiting: Waiting is another kind of waste that lean production methodology suggests eliminating. Waiting refers to the time spent waiting to start the next process or interruptions in the overall production process. Lean production suggests that constant and continuous production should be maintained to avoid resource waste.

- Overproduction: Producing little more than the demand is all right but overproduction way beyond demand can be risky and result in resource wastage. Hence, lean production suggests eliminating overproduction waste.

- Inventory: Finished goods that have not been sold or the production of unfinished goods that have not been moved to the next production stage can create waste.

- Transport: The cost involved in transportation can lead to waste. Movement of material or finished goods should be planned so as to avoid waste of resources.

- Processing: Unnecessary and unrequested over-processing of products can lead to waste.

- Motion: The movement of elements within the organization must be minimized and the path should be planned out in advance to avoid time waste.

Mura

‘Mura’ means unevenness in the production process. It is any kind of non-uniformity in manufacturing that can lead to Muda, which refers to general product waste. Lean production suggests that all processes should be uniform, which can help in ongoing levelled production, avoiding the accumulation of waste or overproduction.

Mura can be avoided with the Just-in-Time (JIT) production system which suggests producing only when there is demand for the product, in the right quantity and the right place.

To learn more about JIT check out our explanation Just-in-time production

In reality, it is very difficult to understand the optimal level of production due to ever-changing demands. But if the production changes in sync with demand, one can avoid Mura.

In the warehouse, where labour is demanded on a day-to-day basis, there is a high chance of Mura. For example, a company might summon 5 employees on Day 1 when there is a surplus of work. On Day 2, when the workload is scarce, 8 employees are called in. This creates an unevenness of labour.

Muri

Muri refers to the overburden. Overburden can happen for both people and machines. Anything that is used beyond its optimal capacity can give negative results. Similarly, if the machines or humans are overburdened with work, it can lead to inefficiency or failure in overall productivity. Muri can be caused by Mura (unevenness) and also excessive removal of Muda (waste).

Muri can be understood in very simple terms of day-to-day life. Most employees are overburdened with work due to cost-cutting and are expected to work overtime or finish the work beyond their capacity to complete a task in a set time. This could result in health issues for the employees, eventually leading to less productivity. Lean production suggests that it is very important to balance Muda, Mura, and Muri to increase productivity and add value to the customers.

Advantages of lean production

There are many advantages to implementing a lean production system. Here are some of the most significant benefits:

Reduced Waste: One of the primary advantages of lean production is that it helps to identify and eliminate waste in all aspects of the production process. This includes reducing excess inventory, minimizing defects and rework, and streamlining production flow.

Increased Productivity: Lean production methods are designed to improve productivity by eliminating bottlenecks. This helps to ensure that products or services are delivered to customers as quickly as possible.

Improved Quality: Lean production techniques prioritize quality by identifying and addressing the root causes of defects and errors. This results in higher quality products or services.

Enhanced Flexibility: Lean production methods allow companies to be more flexible and responsive to changes in customer demand. By using just-in-time production, companies can quickly adapt to changes in the marketplace, reducing the risk of overproduction or excess inventory.

Improved Customer Value: Lean production ultimately results in a better overall customer experience, by delivering high-quality products or services more efficiently and at a lower cost.

Disadvantages of lean production

While there are many advantages to implementing a lean production system, there are also some potential disadvantages, such as:

- High initial Investment: Implementing a lean production system often requires a significant investment in equipment, training, and other resources. This can be a barrier to entry for smaller companies with limited resources.

- Complexity: The lean production system is a complex methodology that requires careful planning and execution. It can be difficult to implement and manage, especially in larger organizations with multiple departments or facilities.

- Dependence on Suppliers: Lean production often requires a close partnership with suppliers, who must be able to deliver high-quality materials and components in a timely manner. If a supplier fails to deliver on time or delivers defective materials, it can cause significant disruptions to the production process.

- Employee Resistance: Enforcing a lean production system can be a significant change for employees, who may be resistant to the new approach or require extensive training to fully understand the new processes and workflows.

- Narrow focus on cost reduction: Lean production is often associated with cost reduction and efficiency improvements, which can sometimes lead to a narrow focus on these goals at the expense of other important aspects of the business, such as innovation or employee satisfaction.

Lean production advantages and disadvantages

The advantages and disadvantages of lean production can be summarized as follows:

| Advantages | Disadvantages |

|

|

Lean production examples

There are many companies across the world, besides Toyota, that implemented a lean production system. Let's take a look at three famous examples of lean production in action:

Boeing: The aerospace manufacturer uses lean production to streamline its production processes and reduce waste. For example, by using just-in-time inventory management and implementing error-proofing techniques, Boeing has been able to improve efficiency and reduce costs in its production of commercial aircraft.

Amazon: The e-commerce giant uses lean production techniques to optimize its supply chain and distribution processes. By using real-time data analysis and just-in-time delivery, Amazon is able to quickly respond to changes in demand and reduce excess inventory.

Intel: The computer chip manufacturer uses lean production to improve the efficiency and quality of its manufacturing processes. By implementing error-proofing techniques and reducing defects, Intel has been able to improve the reliability and performance of its products, while also reducing costs.

Now, let's take a look at a practical and easy-to-understand example of lean production.

Bagel manufacturing company

Before the application of a lean production methodology, there was a waste of 1500 bagels per day due to the difference in size, shapes, different baking processes, etc. The managers decided to have a close look into all the processes and use a lean methodology, correcting the system right where it was resulting in the waste

During their analysis, they found a difference in the processing of each batch, which resulted in a varied production process. Also, inventory was not counted and maintained in the same way for all batches, hence resulting in waste. After correcting the process and following the lean production principle, the waste was reduced to about 50 pieces a day.

The lean production system was developed long ago and is still used in organisations. The system can help in improving processes to a greater extent and at the same time, it adds value for customers. Lean methodology helps with achieving zero waste or maximally reducing waste and balances the production process to get the optimal solution.

Lean production - Key takeaways

- Lean production is also known as lean manufacturing

- Lean production refers to the technique which helps eliminate the maximum level of waste and inefficiency in the production process.

- Lean manufacturing was developed by Toyota and is also known as Toyota Production System

- The advantages of lean production include reduced waste, increased productivity, improved quality, enhanced flexibility, and improved customer value.

- The disadvantages of lean production include high initial investment, complexity, dependence on suppliers, employee resistance, a potential for an overemphasis on cost reduction

- The 5 principles of lean production are value, value stream, flow, pull, and perfection.

- Examples of companies that implemented lean production are Toyota, Boeing, Amazon, and Intel.

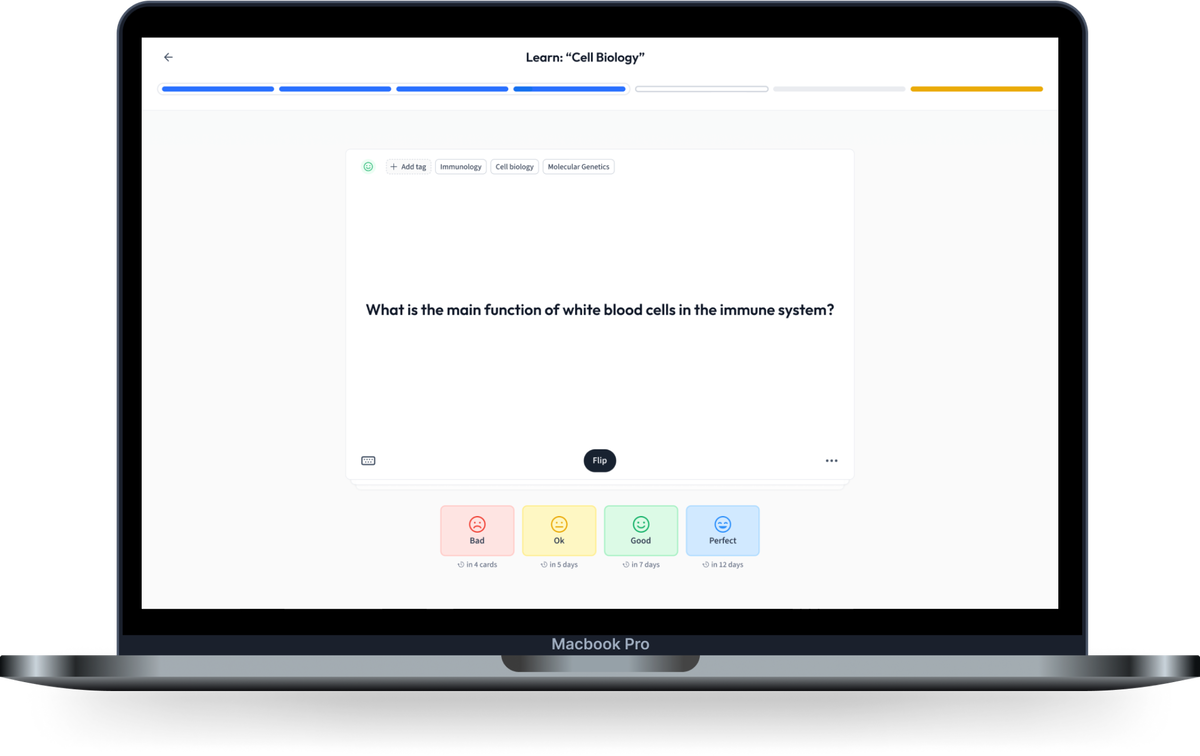

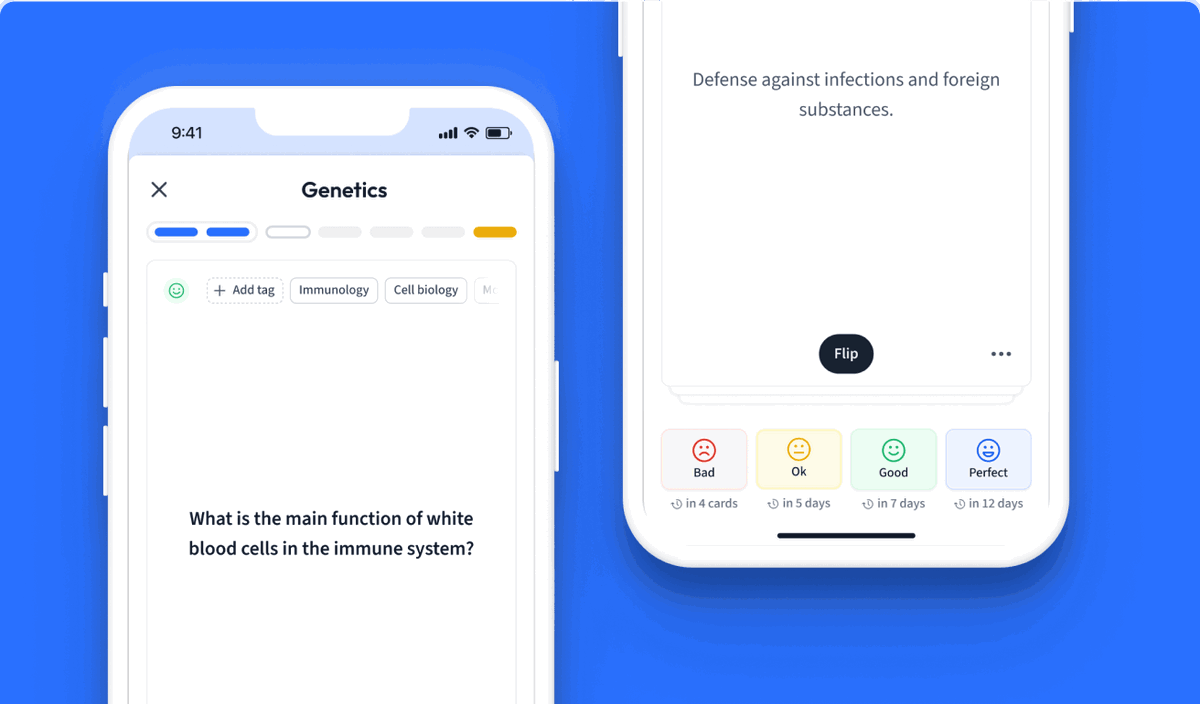

Learn with 28 Lean Production flashcards in the free StudySmarter app

We have 14,000 flashcards about Dynamic Landscapes.

Already have an account? Log in

Frequently Asked Questions about Lean Production

What is lean production?

Lean production refers to a technique that helps eliminate waste and inefficiency in the production process. Here, waste can be defined as anything that does not add value to the production process and for customers. It eliminates all kinds of possible waste at all levels of production to increase the value for customers.

How is lean production associated with JIT?

Just-in-time (JIT) is a production method where a business only produces what is required to keep the stock level at a minimum, making sure that no surplus is produced, thereby reducing or avoiding waste.

Lean production refers to a technique that helps eliminate waste and inefficiency in the production process, also aimed at reducing or avoiding waste to add value to the production process and for the customers.

What is an example of lean manufacturing?

A bakery baked 500 muffins per day, which lead to wastage of about 150 per day. The application of lean production helped the bakery reduce their waste by 75%.

What are the principles of lean production?

The 5 principles of lean production are:

- Value

- Value Stream

- Flow

- Pull

- Perfection.

What is the purpose of lean production?

The purpose of lean production is to reduce waste during the production process to increase the value of the production process, and the value for customers.

What is lean manufacturing?

Lean manufacturing, also known as lean production, eliminates all kinds of possible waste at all levels of production to increase the value for customers. The concept of lean manufacturing was developed by Toyota to reduce waste and inefficiency in their manufacturing process.

What are the 7 losses in production?

The seven losses in production according to lean manufacturing methodology are:

- defects,

- waiting time,

- overproduction,

- inventory (not sold or unfinished products),

- transport,

- unnecessary and unrequested over-processing,

- motion of elements withing the organisation.

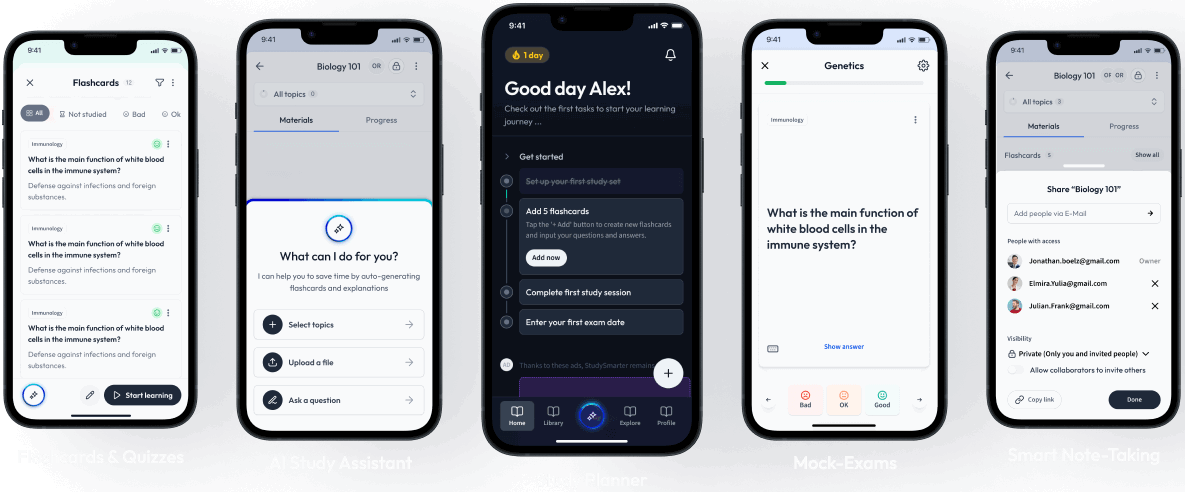

About StudySmarter

StudySmarter is a globally recognized educational technology company, offering a holistic learning platform designed for students of all ages and educational levels. Our platform provides learning support for a wide range of subjects, including STEM, Social Sciences, and Languages and also helps students to successfully master various tests and exams worldwide, such as GCSE, A Level, SAT, ACT, Abitur, and more. We offer an extensive library of learning materials, including interactive flashcards, comprehensive textbook solutions, and detailed explanations. The cutting-edge technology and tools we provide help students create their own learning materials. StudySmarter’s content is not only expert-verified but also regularly updated to ensure accuracy and relevance.

Learn more