Understanding Just In Case Inventory Management

Just in Time and Just in Case inventory models are two fundamental concepts that you will often come across in your business studies. These terms are integral to inventory management systems and heavily influence a company's operational efficiency. In this article, your focus will be on gaining a deep understanding of Just In Case inventory management and how businesses utilize this model to their advantage.

The term "Just in Case" is coined based on the idea of keeping excess stock on hand 'just in case' there are sudden, unpredictable increases in demand or disruptions in supply. This management strategy is traditionally associated with higher levels of safety stock and is used to proactively mitigate the risks related to these uncertainties.

Fundamental Explanation: What is Just In Case Inventory Management?

Just In Case (JIC) inventory management strategy involves maintaining larger inventories to act as a buffer against potential disruptions in supply or changes in customer demand. It is the opposite of the "lean" inventory management approach, like the Just In Time (JIT) model, as it prioritizes availability over efficiency. The JIC strategy aims to prevent stockouts and ensure the steady availability of products for consumers.

Stockouts: A situation where the inventory level for a particular product goes down to zero and the business is unable to meet customer demand for that product. It is a situation that businesses aim to avoid as it can lead to lost sales and damage the company's reputation.

Suppose you run a retail business that sells winter coats. Using the JIC strategy, you would keep an ample stock of coats throughout the year, not just in the colder seasons. This strategy allows you to meet any unexpected surge in demand, say because of an early onset of winter or extremely chilly summer nights. By doing so, you avoid potential stockouts and keep your customer service level high.

Theories behind Just In Case Inventory Management

The Just In Case inventory management model is rooted in certain theoretical assumptions. It fits businesses operating in an unpredictable environment where sales are unstable, and procurement lead times are uncertain. Rather than focusing on efficiency and minimal inventory like the Just In Time model, the JIC approach is designed for stability and preparedness, valuing customer service over inventory carrying costs

Lead Time: The period between the initiation and execution of a process. In inventory management, it refers to the period from when a new order is placed until its delivery. Lead time uncertainty can result in a mismatch between supply and demand, leading to stockouts or overstocks.

The following theories and assumptions cement the JIC approach:

- Demand is unpredictable and can vary greatly.

- Supply chain disruptions are a common occurrence that businesses should proactively manage.

- The costs associated with stockouts (lost sales, reputation damage) outweigh the costs of carrying extra inventory.

To apply this to a real-world scenario, consider a company that manufactures heavy machinery used in construction. The demand for these products can be quite erratic, making it difficult to predict sales accurately. Unexpected large orders or parts procurement delays could significantly impact production. By implementing a JIC inventory management strategy, the company would maintain a buffer of extra inventories to account for these uncertainties, ensuring that they can fulfil customer orders promptly, even under unpredictable circumstances.

Advantages of Just In Case Inventory Management

While Just In Case (JIC) Inventory Management may, at first glance, seem overly cautious, it offers several distinct advantages. Key among these are minimized stockouts, improved customer satisfaction rates, greater flexibility in terms of demand variations, and providing a safety net against supply chain disruptions. All these benefits bolster the company's operational resilience and ultimately contribute towards its long-term success.

The Strategic Benefits of Just In Case Inventory Management

When a company adopts the Just In Case inventory management approach, it's making a strategic decision to manage the unpredictability of supply and demand. Let's delve deeper to understand why a firm might opt for this strategy despite the higher inventory carrying costs.

- Availability: Arguably the most prominent advantage of this model is that it keeps stock readily available for customers. By maintaining larger safety stocks, firms can cater to unexpected demand surges without suffering from dreaded stockouts.

- Risk Mitigation: If you're in a business environment with a higher probability of supply chain disruptions (due to limited suppliers, adverse weather conditions, transportation issues etc.), then having a Just In Case inventory can act as your insurance policy.

- Customer Satisfaction: Service level, the percentage of demand met from on-hand inventory, is a critical driver of customer satisfaction. With a JIC system, as stocks are readily available, service levels are high, directly contributing to enhanced customer satisfaction.

- Stability: The JIC model can offer more stability to production and sales operations. As buffer stock is maintained, even if demand fluctuates or there are supply issues, the business can continue to service customers.

Service Level: In inventory management, this term refers to the likelihood that a demand for a particular item will be met using the on-hand inventory without having to wait for a new order to arrive. It's typically expressed as a percentage - a 95% service level would mean that 95 out of every 100 customer orders can be met using items in stock.

One crucial understanding about the JIC system is that it is not about amassing inventory haphazardly. Instead, the strategy involves striking a balance to maintain a safety stock that can mitigate the risks of demand-supply mismatch while taking into account carrying costs. Firms need to analyse their supply chain vulnerabilities, customer demand patterns and the cost implications of stockouts vs overstocks to determine an optimal safety stock level.

Practical Examples of Just In Case Inventory Management Advantages

Let's extrapolate the theoretical advantages of Just In Case inventory management into practical, real-world benefits through some examples from different industries.

Consider a pharmaceutical company that manufactures life-saving drugs. The demand for such medicines can be erratic, and the consequences of stockouts are severe. In this case, adopting a JIC inventory model can ensure the continual availability of these medicines, preventing potential life-threatening situations. Here, the cost of carrying extra inventory far outweighs the risk associated with stockouts.

Another example can be a retail store specialised in seasonal products, like Christmas decorations. Basing on previous sales records, they might anticipate demand, but sudden weather changes or unpredictable consumer behaviour can lead to demand spikes. By maintaining a safety stock 'just in case,' they can cater to such unforeseen sales surges and capitalise on the superior sales opportunities.

Lastly, think about businesses that source materials or parts from overseas suppliers. Given the potential for shipping delays or interruptions due to trade restrictions, having a JIC inventory provides a buffer to continue operations seamlessly despite these uncertainties.

Apple provides an interesting case study. Although they follow a primarily Just In Time methodology, like many other tech companies, they also maintain a certain discharge inventory level. After the 2011 Japan earthquake, Apple faced supply chain disruptions as several of their critical component manufacturers were based in the affected region. As per their annual report, they maintained alternative sourcing arrangements and enough buffer inventory to handle such contingencies, clearly demonstrating the value of the JIC strategy.

Techniques Utilised in Just In Case Inventory Management

Operationalising a Just in Case (JIC) Inventory Management strategy requires more than merely deciding to keep extra stock on hand. It involves a sophisticated mix of techniques and methods designed to forecast demand, determine the right level of safety stock, coordinate with suppliers, manage warehouse space, and analyse costs. This allows companies not only to handle the uncertainties but also keep the supply chain cost-effective.

Essential Techniques in Just In Case Inventory Management

Effective management of Just In Case inventory strategy requires deployment of certain techniques to maintain efficiency and cost-effectiveness. Techniques like demand forecasting, safety stock calculation, supplier management and cost analysis are indispensable to this inventory management strategy. Let's delve deeper into each of these techniques:

Demand Forecasting:

Demand forecasting is the process of estimating the future demand for a product. Accurate demand forecasting is crucial for maintaining the right level of safety stock. It involves analysing historical sales data, market trends, and other relevant factors. Businesses may use statistical techniques like time series analysis or regression analysis to forecast demand.

Time Series Analysis: It is a statistical technique that deals with time series data, or trend analysis. It allows businesses to identify patterns and trends in historical data and make future predictions based on those patterns.

Safety Stock Calculation:

Safety stock is the additional stock kept aside to guard against potential stockouts. To determine the optimal safety stock level, businesses must consider factors such as the desired service level, demand and supply variability, and lead time. The most common formula for safety stock calculation is:

\[ Safety Stock = (Maximum Lead Time - Average Lead Time) \times (Maximum Demand - Average Demand) \]This formula calculates safety stock based on the difference between maximum and average lead time, and the difference between maximum and average demand.

Safety Stock: It is the excess inventory that a company holds to protect against variability in market demand and lead time. In a nutshell, safety stock acts as a buffer against potential stockouts.

Supplier Management:

Effective supplier management is a key component of any JIC strategy. It involves maintaining strong relationships with suppliers, monitoring their performance and communication. Both the quality and lead time of supply hinge significantly on the strength of these relationships, therefore, supplier reliability is crucial in a JIC system.

Supplier Management: It is the process of maintaining positive and effective relationships with the suppliers of a business. It includes monitoring and managing supplier performance, ensuring timely delivery of goods and maintaining quality control.

Cost Analysis:

Carrying extra inventory incurs costs, including storage, insurance, spoilage, and depreciation. Therefore, businesses adopting JIC strategy should conduct regular cost analysis to ensure that the benefits of carrying extra inventory outweigh the carrying costs. If the cost of carrying extra safety stock exceeds the cost of a potential stockout, it may be time to revise the safety stock level.

Cost Analysis: It involves the method of evaluating the different costs involved in a business operation or project. In the context of inventory management, this could include comparing holding costs, ordering costs, and shortage costs.

Just In Case Inventory Management: Practical Techniques and Their Application

These techniques are not used in isolation, and the effective management of Just In Case inventory strategy often involves all these methods applied together. Not only its implementation but also periodic review for continuous improvement is essential.

Consider an online retail business that keeps a JIC inventory. Based on past sales data and market trend analysis, it forecasts expected demand for the next quarter. Using the demand variability and lead time variability data, it calculates the safety stock level. The company also invests considerably in building solid relationships with its suppliers to ensure timely and quality delivery. Regular cost analysis is conducted to optimise carrying costs and the safety stock level is revised accordingly.

Firms also make use of technologies like ERP and SCM systems to manage these processes seamlessly. Advanced analytics and AI also play an increasing role in accurate demand forecasting and for optimal safety stock calculation.

The power of data cannot be underrated in the context of JIC inventory management. With the advent of Big Data and advanced analytics, businesses can now use an enormous amount of data to their advantage, improving the precision of their demand forecasting and making their JIC strategy more effective. For instance, machine learning algorithms can make accurate predictions based on patterns in large datasets, making them highly useful in forecasting demand and determining optimal safety stock levels.

Just In Case vs Just In Time Inventory Management

Just In Case (JIC) and Just In Time (JIT) represent two fundamentally different approaches to inventory management. These strategies, while both have their distinct pros and cons, serve different business environments and operational requirements. Understanding the key differences between Just In Case and Just In Time inventory management can help you choose the right approach for your business.

Understanding the Differences: Just In Case vs Just In Time

The key difference between JIT and JIC lies in their approach to the uncertainty and variability of demand. JIC, as you've learnt before, prepares for the worst-case scenario. It seeks to minimise the risk of stockouts by maintaining safety stock. It emphasises availability and customer service at the cost of potentially higher inventory carrying costs.

JIT, on the other hand, seeks an almost diametrically opposite approach. This strategy focuses heavily on efficiency and aims to virtually eliminate stock other than what is required for immediate production or sales. The approach aims to deliver right quantities at the right time, thereby significantly reducing carrying costs associated with holding inventory.

For JIT, accurate demand forecasting and efficient, reliable suppliers are even more critical than the JIC model. Without accurate demand prediction and reliable suppliers, JIT strategy would fail, leading to costly stockouts or interruptions in production. This might lead to missed delivery deadlines and dissatisfied customers.

Critical Differences: Just In Case vs Just In Time

The crux of the difference between the two systems can be encapsulated under four critical aspects:

- Focus: While the JIC system is demand-oriented and focusses on avoiding stockouts, the JIT system is supply-oriented and focusses on exact timing of supply to reduce storage costs.

- Supply Chain: JIC system’s success is less dependent on the suppliers as large safety stock is maintained. But, JIT system requires highly reliable suppliers as it works on tight schedules.

- Inventory Levels: Clearly, the JIC approach results in higher inventory levels to cater to fluctuating demand, whereas JIT requires minimal inventory as supplies arrive exactly when needed.

- Risk: JIC carries the risk of excessive inventory costs, while JIT carries the risk of stockouts if any unforeseen supply chain disruption occurs.

Just In Time (JIT) inventory management: This is an inventory strategy where materials, goods and labour are scheduled to arrive exactly when needed in the production process, closely aligning it to actual customer demand. The primary focus in a JIT system is the reduction of waste from overproduction and excess inventory.

Comparing Just In Case and Just In Time Inventory Management

Understanding how JIT and JIC compare will help you decide which model aligns best with your firm's operational strategy and business environment. Here, we will outline the key factors to consider, including cost considerations, risk exposure, supplier dependency, and flexibility.

Side-by-Side Comparison of Just In Time and Just In Case Inventory Management

Refer to the table below to understand the differences between Just In Case and Just In Time Inventory Management better:

| Criteria | Just In Case (JIC) | Just In Time (JIT) |

| Cost Considerations | Potentially higher inventory carrying cost due to safety stock. | Lower inventory carrying cost as inventory is minimised. |

| Risk Exposure | Lower risk of stockouts, higher risk of obsolete inventory. | Lower risk of obsolete inventory, higher risk of stockouts if demand or supply fluctuates. |

| Supplier Dependency | Less dependent on reliable suppliers because of safety stock. | Requires highly reliable suppliers because supplies are ordered 'just in time'. |

| Flexibility | Can handle demand fluctuations better due to buffer stock. | Faster response to market since it's closely tied to actual demand, but less flexible for demand spikes. |

Obsolete Inventory: These are items that have become out-of-date or will no longer be used. Neglecting the movement and clearance of obsolete inventory can lead to considerably higher inventory carrying costs.

A fashion retailer selling seasonal clothing can leverage JIT strategy to avoid carrying heavy inventory of out-of-season clothes. Meanwhile, a pharmaceutical company manufacturing life-saving drugs might favour a JIC strategy to ensure patient needs can always be met immediately, even in the face of unpredictable demand fluctuations.

It's worth noting that JIT and JIC are not 'one-size-fits-all' solutions, and companies often combine elements from both types of inventory management to strike a balance between cost efficiency and service level. For instance, Amazon uses a hybrid model, holding popular items in a JIT manner to quickly serve customer demand, while also holding safety stock of critical items with long lead times. This hybrid approach offers both the cost benefits of JIT and the risk mitigation of JIC.

The Risks of Just In Case Inventory Management

While the Just In Case (JIC) inventory management approach can protect against uncertainties like fluctuating customer demands and delays in delivery, it isn't without its potential pitfalls. It's essential to understand the risks associated with this strategy in order to manage them effectively and ensure sustainable operations.

Understanding the Risks Associated with Just In Case Inventory Management

Organisations adopting the JIC approach tend to hold excess inventory, known as safety stock, to offset demand variability and avoid the cost of lost sales due to stockouts. However, keeping additional stock on hand comes with its own set of challenges. These challenges stem from costs associated with inventory management, issues with excess stock, and exposure to supply chain disruptions. Let's explore some of these risks in further detail.

Increased Holding and Carrying Costs:

The very nature of the JIC strategy results in an increase in inventory levels. This, in turn, leads to increased costs associated with storage, handling, insurance, and overheads. Extended holding periods can also result in a tie-up of working capital and potentially hinder the organisation's liquidity.

Holding and Carrying Costs: These are the costs incurred by an organisation to store and maintain its inventory. This includes warehousing costs, handling costs, insurance, and the cost of capital tied up in inventory.

Risk of Obsolescence:

Another risk associated with the JIC strategy is that of obsolescence. Trends change, technologies advance and customer preferences evolve with time. In such a dynamic environment, the excessive stock held as part of a JIC strategy may run the risk of becoming obsolete or out-of-date before it can be sold to customers.

Wastage and Spoilage:

For businesses dealing with perishable goods or products with short shelf lives, there is an added risk of spoilage. Even non-perishable goods and components could be damaged or lost. Maintaining larger quantities of such items as part of a JIC strategy may lead to increased instances of waste and spoilage.

Mitigating the Risks in Just In Case Inventory Management

Given the potential risks associated with JIC inventory management, it's crucial to have measures in place to mitigate these risks. Neglecting them might lead to escalated costs, decreased profitability, and strained customer relationships. Here are some strategies for risk mitigation in the context of JIC inventory management:

Regular Review and Update of Safety Stock Levels:

One way to mitigate risks associated with JIC inventory management is to regularly review and update safety stock levels. By accurately predicting demand and adjusting safety stock levels accordingly, you can avoid excess stock while still remaining prepared for demand fluctuations.

Effective Stock Rotation and Warehouse Management:

Effective management of warehouse space and implementing stock rotation practices, especially for perishable goods, can help minimise spoilage. This includes the practice of 'First-In-First-Out' (FIFO) where the oldest stock is sold first, thus reducing the chance of obsolescence or spoilage.

FIFO (First-In-First-Out): This is a method for organising and manipulating a data buffer, where the oldest (first) entry, or 'head' of the queue, is processed first. In terms of inventory management, this means that the stock that was received first is sold first. This method is particularly useful in inventory management of perishable goods.

Consider a supermarket chain that utilises a JIC inventory approach. To minimise the risk of perishable goods spoiling, the supermarket employs the FIFO stock rotation method. The items that were stocked earlier are placed upfront, making sure they are sold before newer stock. Through this method, the supermarket can mitigate wastage and maintain the freshness of their produce.

Implementing Efficient Inventory Management Systems:

Investing in an efficient inventory management system can help automate and streamline the inventory processes, providing realtime visibility and control over inventory. This can help in better demand forecasting, efficient stock rotation, and control over warehouse operations, thereby reducing the risks associated with JIC inventory management.

Remember, the key to successful JIC inventory management lies in balancing the need to meet uncertain demand with the costs and risks of holding extra inventory.

Advanced technologies like Big Data Analytics and AI can play a pivotal role in mitigating the risks associated with JIC strategy. These technologies can handle complex data to make accurate demand forecasts, optimise safety stock levels, and even predict potential changes in consumer behaviour or market trends. So while adopting a Just In Case inventory strategy, it is worthwhile for firms to explore these technological tools and integrate them in their inventory management system for risk mitigation.

Just In Case Inventory Management - Key takeaways

- Just In Case Inventory Management: An inventory management strategy where businesses maintain a safety stock to mitigate the risks of demand-supply mismatch, taking into account carrying costs.

- Service Level: The likelihood that a demand for a particular item will be met using on-hand inventory without having to wait for a new order to arrive.

- Demand Forecasting: The process of estimating future demand for a product, which is crucial for maintaining the right level of safety stock.

- Safety Stock: The additional stock kept aside to guard against potential stockouts. The optimal safety stock level is determined considering factors like the desired service level, demand and supply variability, and lead time.

- Just In Case vs Just In Time inventory management: Two fundamentally different approaches to inventory management. JIC focuses on availability and customer service at the cost of potentially higher inventory carrying costs. JIT focuses on efficiency, aiming to virtually eliminate stock other than what is needed for immediate production or sales.

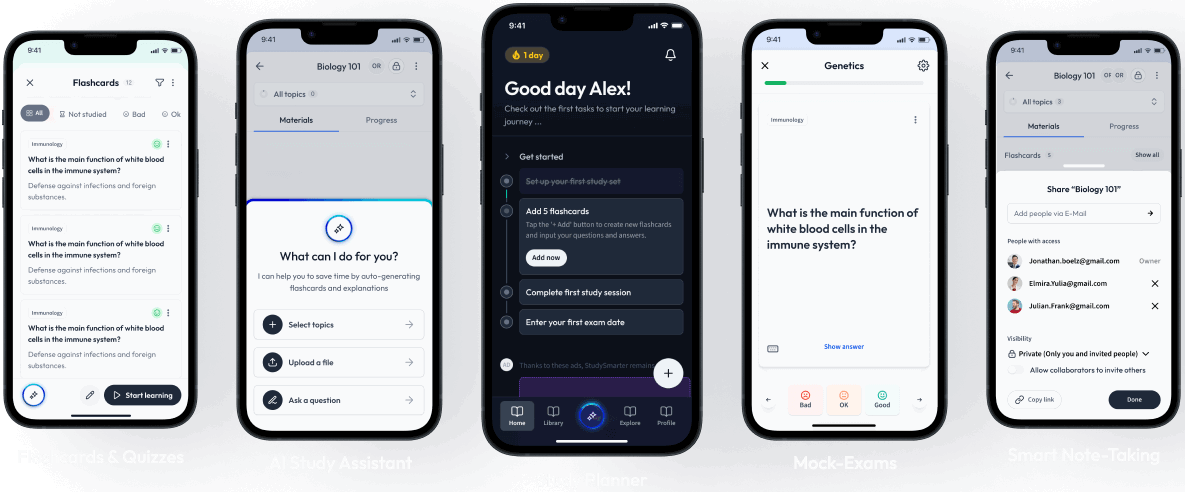

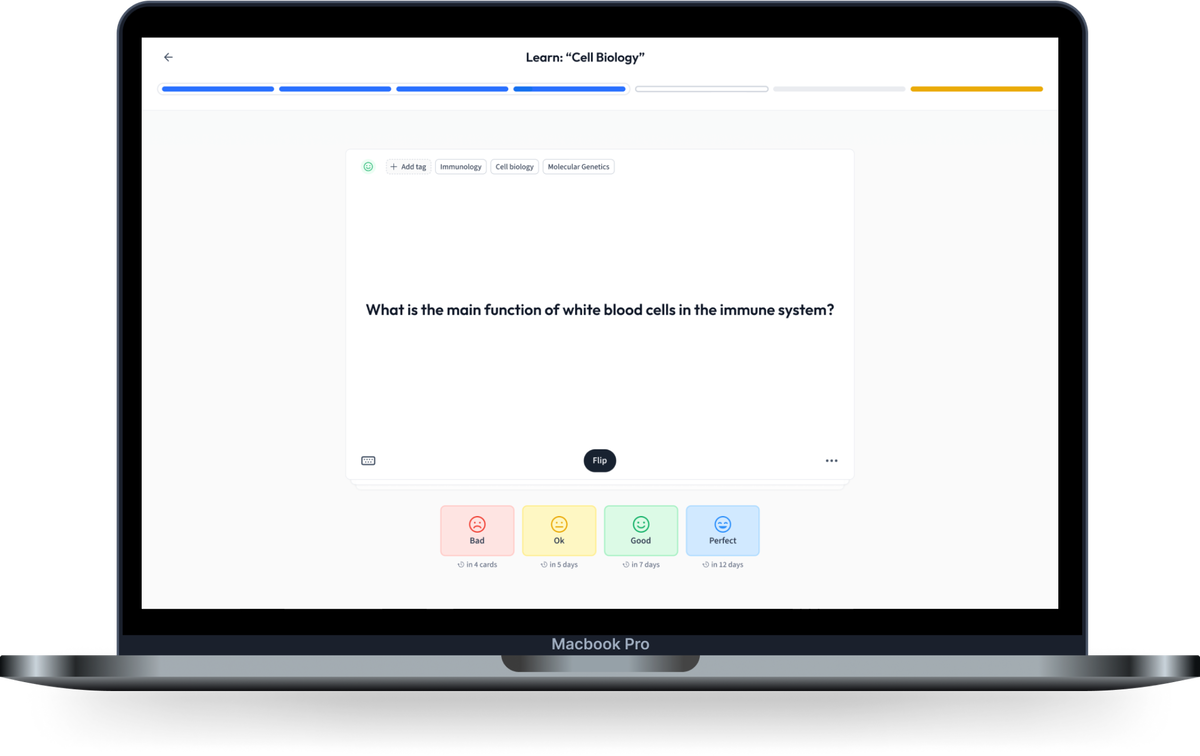

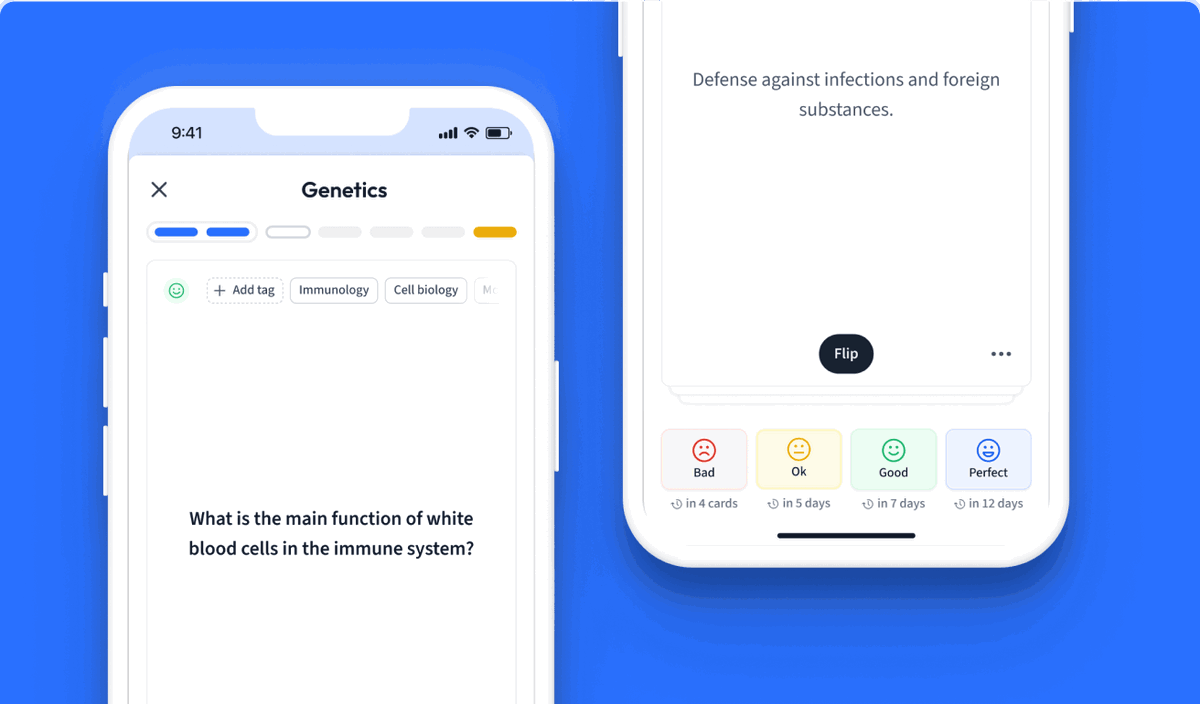

Learn with 40 Just In Case Inventory Management flashcards in the free StudySmarter app

We have 14,000 flashcards about Dynamic Landscapes.

Already have an account? Log in

Frequently Asked Questions about Just In Case Inventory Management

About StudySmarter

StudySmarter is a globally recognized educational technology company, offering a holistic learning platform designed for students of all ages and educational levels. Our platform provides learning support for a wide range of subjects, including STEM, Social Sciences, and Languages and also helps students to successfully master various tests and exams worldwide, such as GCSE, A Level, SAT, ACT, Abitur, and more. We offer an extensive library of learning materials, including interactive flashcards, comprehensive textbook solutions, and detailed explanations. The cutting-edge technology and tools we provide help students create their own learning materials. StudySmarter’s content is not only expert-verified but also regularly updated to ensure accuracy and relevance.

Learn more